How Air-tow Trailers Are Manufactured

- March 14, 2025

- Uncategorized

- Posted by admin

- Leave your thoughts

At Air-tow Trailers, quality is the foundation of everything we do. From the initial design to the final bolt, our team of skilled professionals ensures that every Air-tow trailer meets the highest standards of durability, safety, and innovation. Let’s take you behind the scenes to see how our operations, engineering, welding, and assembly teams work together to build top-of-the-line trailers. Learn how Air-tow Trailers are manufactured:

1. Operations: Managing Materials & Production Efficiency

Our operations team is the backbone of our manufacturing process. They manage the supply chain, ensure production runs smoothly, and keep everything on schedule. Here’s how they contribute to building every Air-tow trailer:

- Material Sourcing & Inventory Management: We source High-quality steel, precision components, and durable materials to meet our strict standards.

- Production Scheduling: They coordinate with engineering, welding, and assembly teams to keep production timelines on track.

- Quality Control Oversight: Every step of production is monitored to ensure that no defective parts reach the next stage. Our team practices adherence to controlling our quality.

2. Engineering: Designing for Strength & Innovation

Every Air-tow trailer begins with the engineering team. They take concepts and turn them into reality, ensuring each model meets our customers’ needs while maintaining structural integrity and efficiency.

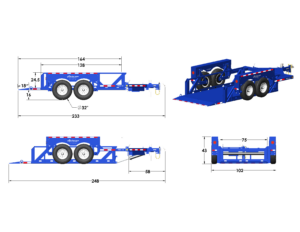

- Trailer Design & 3D Modeling – Using advanced CAD software, our engineers design each trailer with precision, optimizing for weight distribution, load capacity, and aerodynamics.

- Stress Testing & Prototyping – Engineers test every design for durability, using finite element analysis (FEA) and real-world load simulations to ensure the trailer can handle tough jobs.

- Product Data Management (PDM) – All blueprints and technical documents are securely stored in a vault system to ensure consistency, accuracy, and version control.

3. Welding: Crafting the Frame for Durability

Once designs are finalized, the welding team takes over, fabricating the steel frame that serves as the backbone of every trailer.

- Precision Welding of Structural Components— Our welders construct the chassis and frame Using state-of-the-art MIG and TIG welding techniques, ensuring strength and longevity.

- Surface Preparation—Before welding, surfaces must be thoroughly cleaned and prepped to remove contaminants, as welding over impurities can compromise structural integrity.

- Fit Accuracy – Ensuring the fit is accurate and precise for each trailer is a recurring step in the welding process, guaranteeing consistency across all models.

4. Assembly: Bringing It All Together

Once welding is complete, the assembly team takes over, installing key features and making sure everything is in working order.

- Hydraulic System Installation—A carefully assembled hydraulic lift mechanism makes our trailers’ ground-level loading system possible.

- Electrical Wiring & Lighting – Every trailer is fitted with wiring harnesses, LED lighting, and brake systems to ensure compliance with safety regulations.

- Tire Installation – The assembly team ensures that all tires are properly mounted and secured for safe transport.

- Final Fit & Finish – Side panels, and optional accessories like E-tracks, Skid-X, and the Solar Battery Charger are installed, and the trailer receives a final inspection.

- Vinyl Sticker Application – Any necessary branding, safety decals, or instructional stickers are applied to the trailer before it leaves the facility.

5. Final Inspection & Quality Testing

Before any Air-tow trailer leaves the factory, it undergoes a multi-point inspection to ensure it meets our high standards. This includes:

- Hydraulic Testing – We make sure the trailer’s deck raises and lowers as it should and check that the deck is level during the process.

- Brake & Electrical Testing – Ensuring lights, brakes, and wiring systems work flawlessly.

- Overall Durability Check – Inspecting welds, fasteners, and structural components to ensure a long lifespan.

Built to Perform, Built to Last

Every Air-tow trailer is proudly made in the United States and is a product of innovation, craftsmanship, and meticulous attention to detail. Whether it’s used for construction work, landscaping, or heavy equipment transport, our trailers are engineered to perform under pressure.

Want to see an Air-tow trailer in action? Contact us today to find a dealer near you.