Selecting the right trailer starts with choosing the right material. Steel and aluminum each offer unique advantages depending on your specific hauling needs. At Air-tow Trailers, we manufacture high-quality steel trailers designed for strength and reliability, but we also understand that customers want to know how steel stacks up against aluminum. Here’s a fair comparison to help you make the best decision for your operation.

Strength and Durability

Steel: Known for its unmatched strength, steel trailers are ideal for heavy-duty applications. They can withstand rough handling and harsh weather conditions and are less prone to dents and dings than aluminum trailers. This durability ensures longevity, making steel trailers a reliable choice for long-term use.

Aluminum: While lighter than steel, aluminum trailers offer excellent corrosion resistance, making them suitable for marine environments and areas with high humidity. However, aluminum may not provide the same level of impact resistance as steel in specific heavy-duty applications.

Weight and Payload Capacity

Steel: Due to its density, steel trailers are typically heavier than aluminum trailers. The weight can affect fuel efficiency when towing and may require a higher towing capacity vehicle. However, the added weight can also contribute to stability and balance, especially when carrying uneven loads.

Aluminum: Lightweight aluminum trailers are easier to tow, require less fuel consumption, and offer higher payload capacities for their size. Being lighter makes them advantageous for transporting goods where weight reduction is critical.

Maintenance and Longevity

Steel: Regular maintenance, such as rust prevention and painting, is essential to prolonging the life of steel trailers. Proper care can extend their durability and structural integrity, ensuring they remain operational for years.

Aluminum: Aluminum trailers are inherently resistant to rust and corrosion, requiring minimal maintenance in comparison to steel. They are well-suited for owners looking for a trailer with a lower maintenance profile.

Cost Considerations

Steel: Steel trailers are typically more cost-effective initially compared to aluminum trailers. This makes them a preferred choice for budget-conscious buyers looking for an affordable, durable hauling solution.

Aluminum: While aluminum trailers may have a higher upfront cost due to material and manufacturing processes, they often provide cost savings over time due to lower maintenance requirements and better fuel efficiency.

Repairability in the Real World

Steel: Steel trailers are generally easier and more cost-effective to repair. Most dealers or local shops can weld cracks or damage without specialized equipment.

Aluminum: Repairing aluminum trailers can be more expensive and require specialty welding services. If significant damage occurs, this could mean longer turnaround times and higher repair bills.

Custom Modifications & Accessories

Steel: Thanks to its strength and versatility, steel is easier to customize. Whether adding ladder racks, toolboxes, or tie-down systems, steel trailers allow for flexible modifications.

Aluminum: Customization is more limited with aluminum due to its lower structural strength and welding constraints. Some additions may require special hardware or reinforcements.

Performance in Extreme Temperatures

Steel: Steel performs reliably across a wide range of climates. It holds up well in both cold and hot temperatures without becoming brittle or overly flexible.

Aluminum: In frigid conditions, aluminum can become more brittle. Over time, it may be more prone to stress fractures from temperature fluctuations and vibration.

Structural Integrity: Deck Strength & Long-Term Performance

Steel: Steel trailers excel when it comes to long-term structural integrity. Their durable frames handle concentrated weight, like forklifts or scissor lifts, without flexing, making them ideal for heavy-duty, high-point-load applications. Steel also resists fatigue from daily use and repeated stress, maintaining its strength and shape over time. Steel offers confidence under pressure for professionals who rely on consistent hauling day in and day out.

Aluminum: While aluminum performs well in lighter-duty scenarios, it can flex more under heavy, uneven loads. Over time, this repeated flexing may lead to fatigue or structural weakening, especially in high-usage environments. Those transporting lighter goods or prioritizing minimal weight can still choose aluminum but must carefully manage load distribution.

Towing Experience and Handling

Steel: The heavier weight of steel trailers provides a more grounded, stable towing experience. Therefore, there is less sway and better control, especially in high-wind or uneven-road conditions.

Aluminum: Aluminum trailers’ lightweight nature can be easier on your tow vehicle and improve fuel economy, but depending on the load, they may result in more movement or bounce.

Corrosion Resistance: Paint vs. Material

Steel: Modern coatings like powder coating or galvanization significantly improve corrosion resistance. A spray-on bed liner, like Skid-X, may be a beneficial addition to prevent corrosion. With basic maintenance, rust is not an issue for most steel trailers.

Aluminum: Naturally corrosion-resistant, aluminum holds up well without coatings. However, if left untreated over time, it can still oxidize or develop surface blemishes.

Resale Value & Market Perception

Steel: Steel trailers hold substantial resale value, especially in heavy-use industries like construction or landscaping. Buyers appreciate their strength, serviceability, and value retention.

Aluminum: Aluminum trailers also retain good resale value, particularly with recreational users, but structural damage can significantly affect market price due to the complexity of repairs.

Conclusion

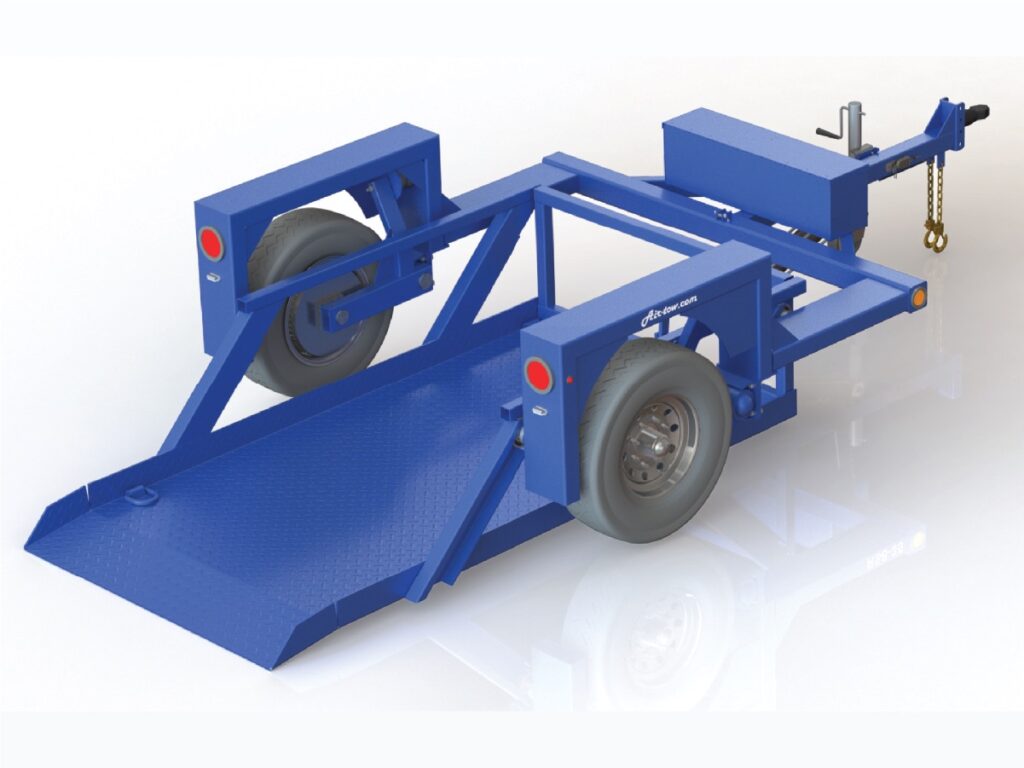

Both steel and aluminum trailers offer benefits depending on your unique hauling needs, environment, and budget. At Air-tow Trailers, we’re proud to build trailers from high-strength steel, which is known for its durability, reliability, and performance under pressure.

Steel is a wise investment if you need a trailer that can withstand daily use, handle heavy loads confidently, and offer real-world repairability. At Air-tow, we deliver peace of mind and lasting performance, whether you’re hauling equipment across job sites or transporting cargo cross-country.

Do you have questions about which trailer is right for your business? Contact us today to learn more about our steel trailer lineup and how we can help you find the perfect fit.